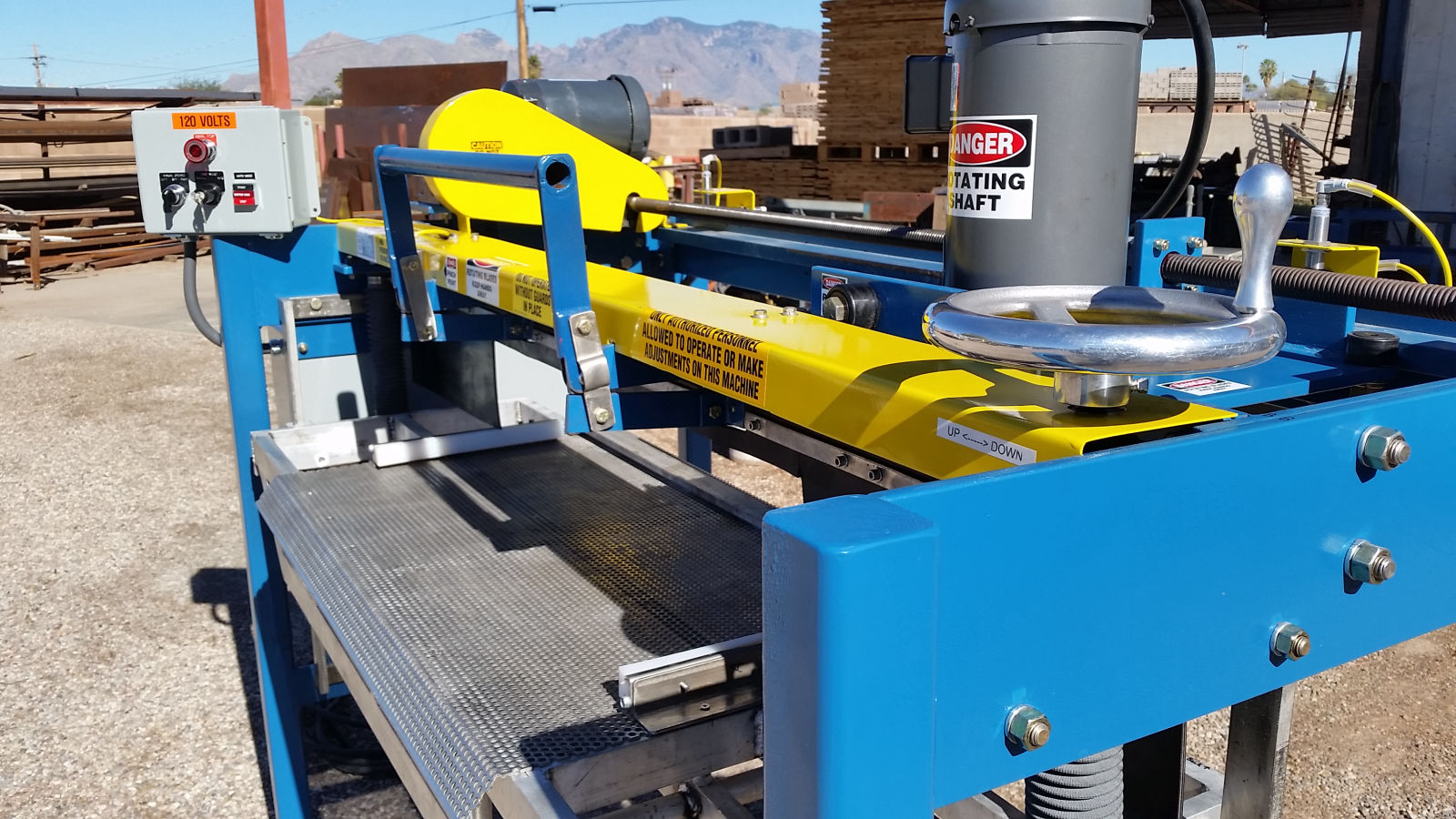

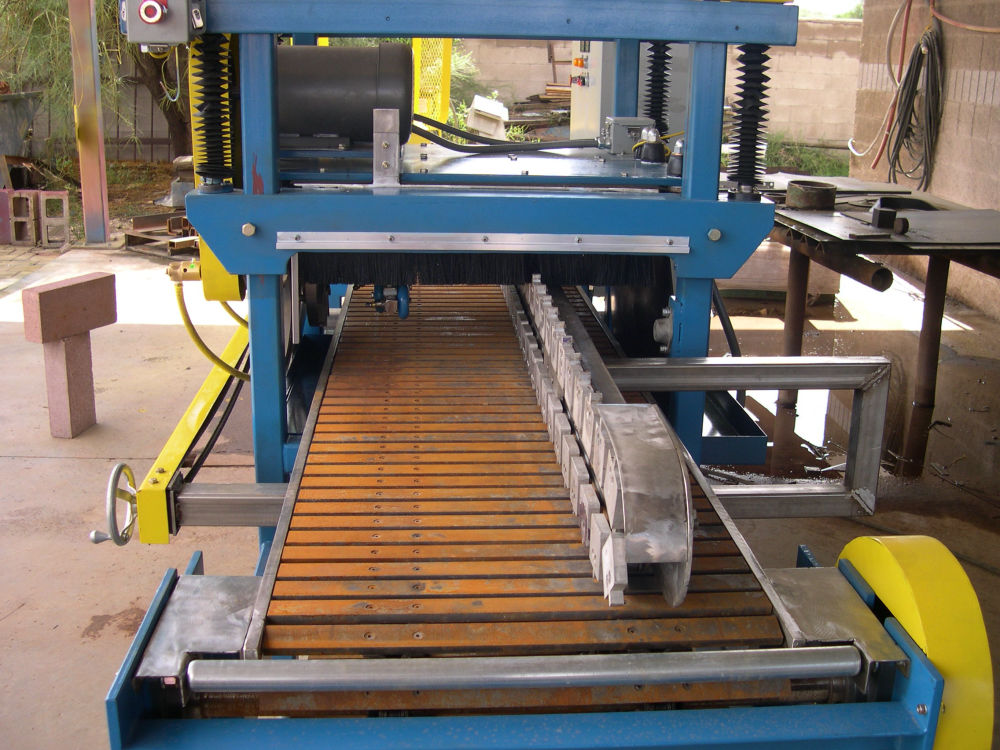

The Model 380-SSH shot blast machine, developed by Advanced Production Manufacture, is by all accounts the only shot blast machine designed and built specifically for masonry units.

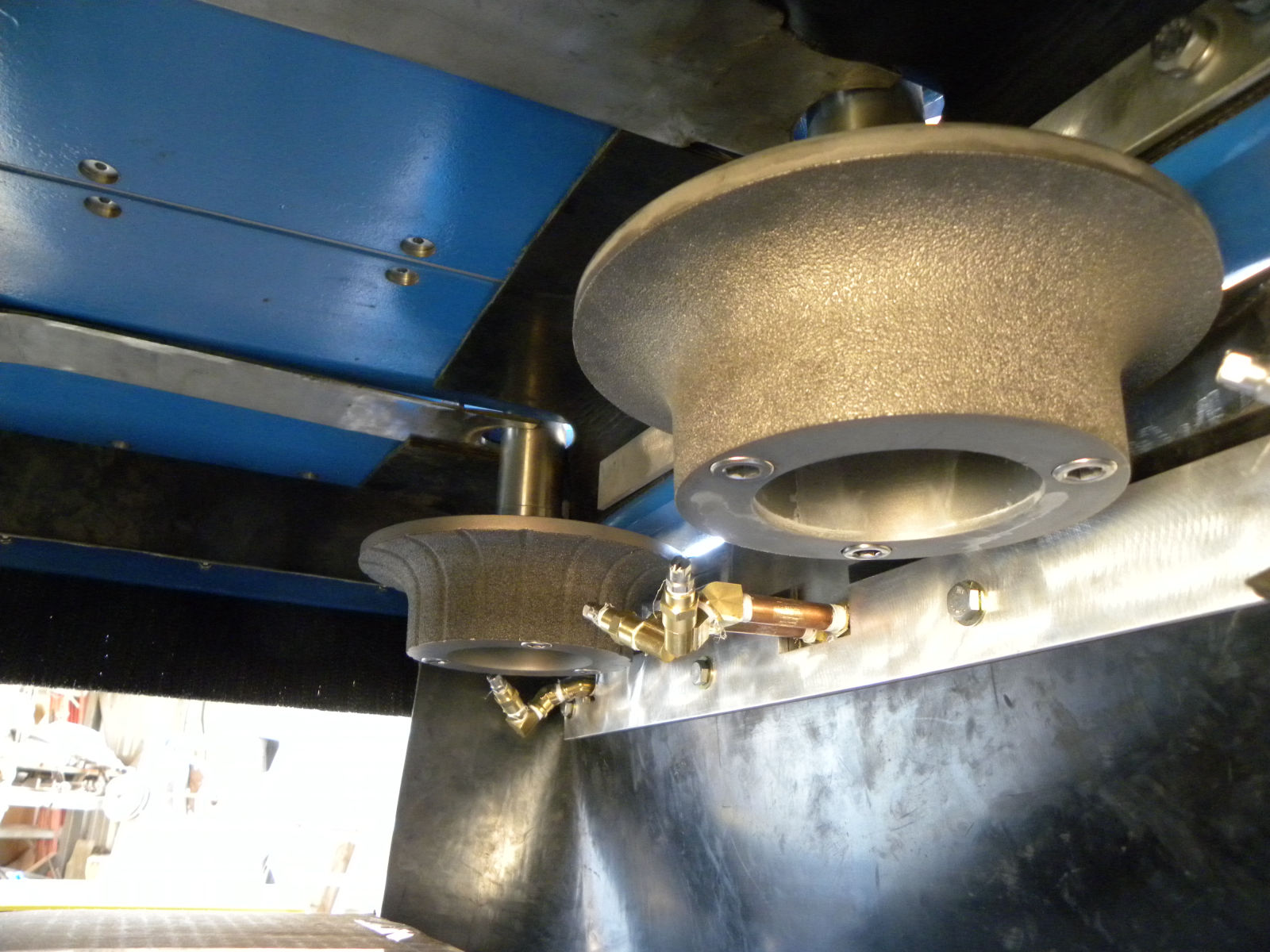

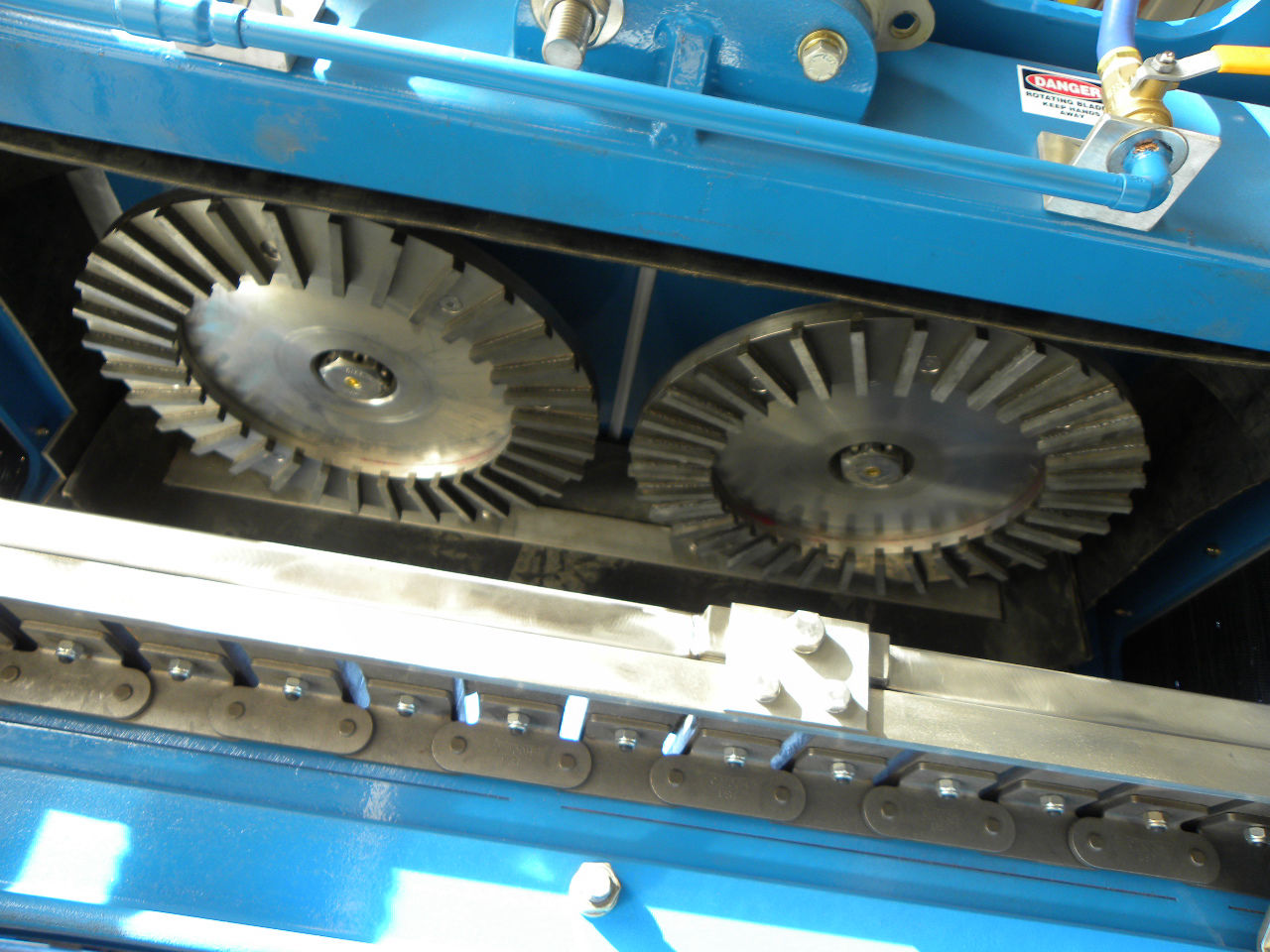

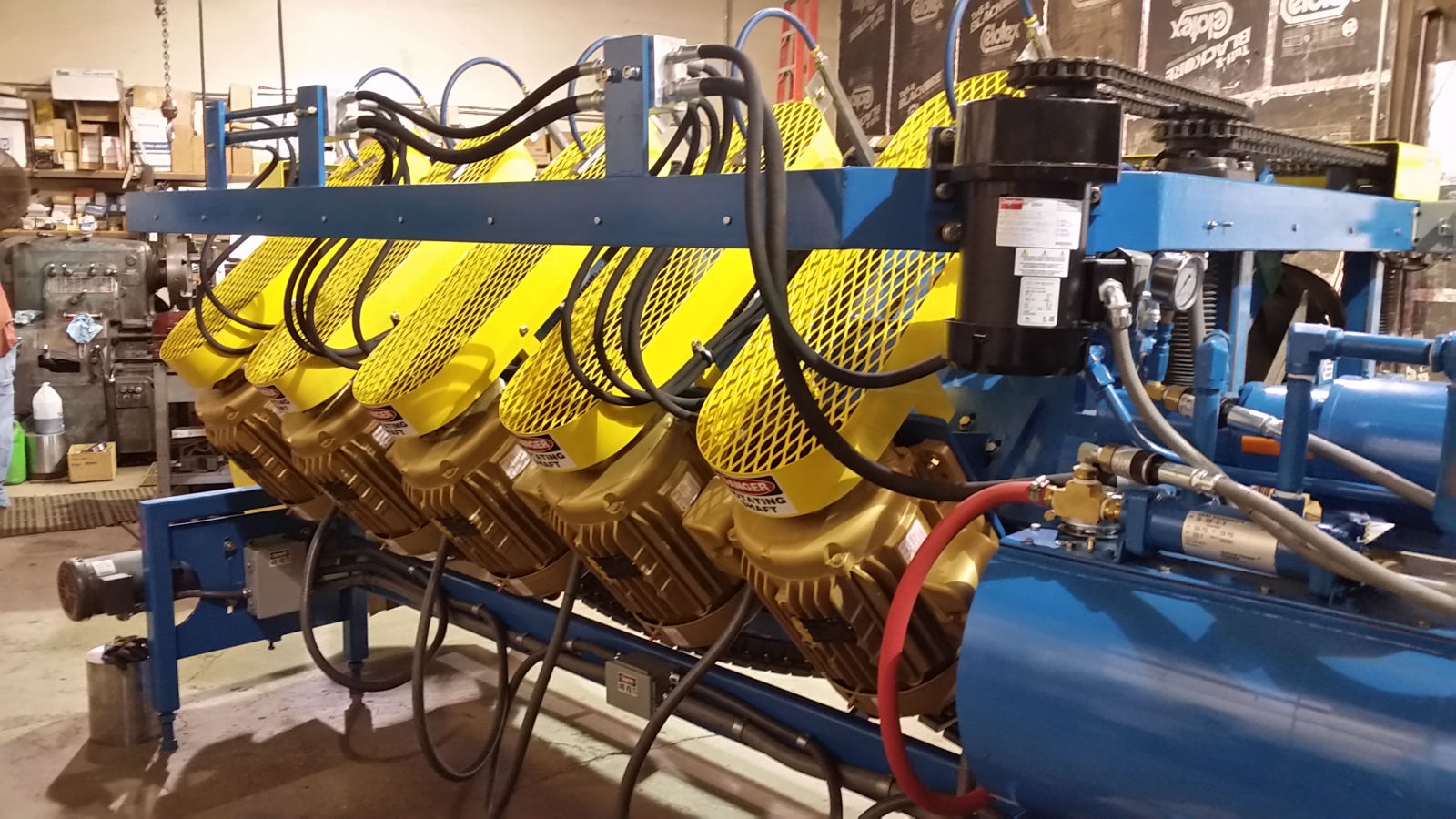

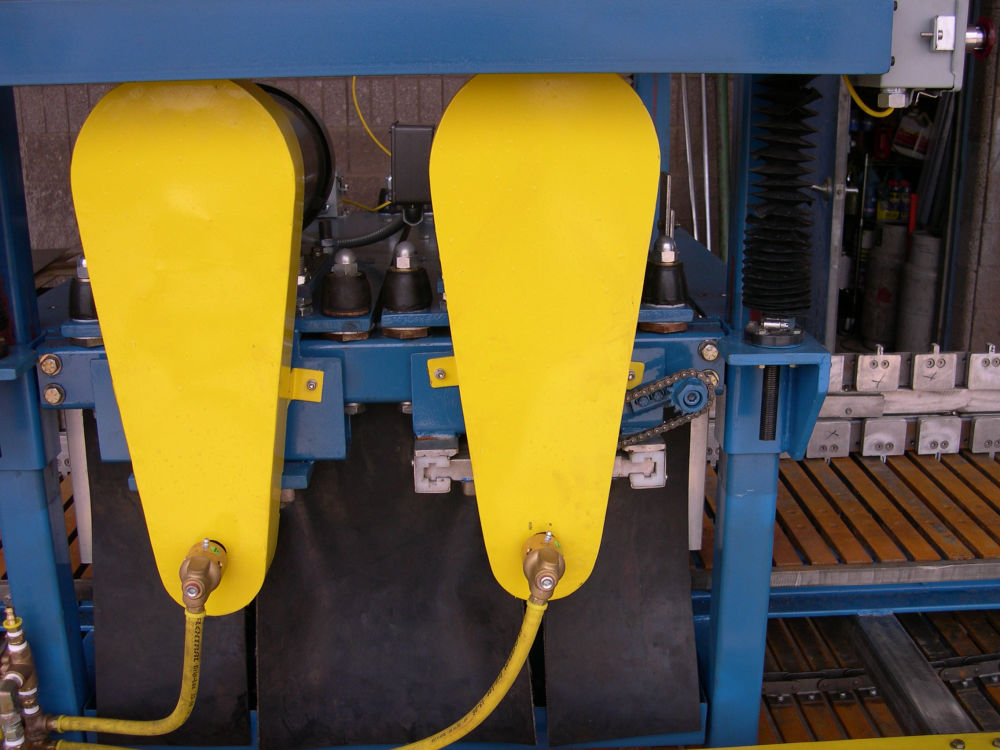

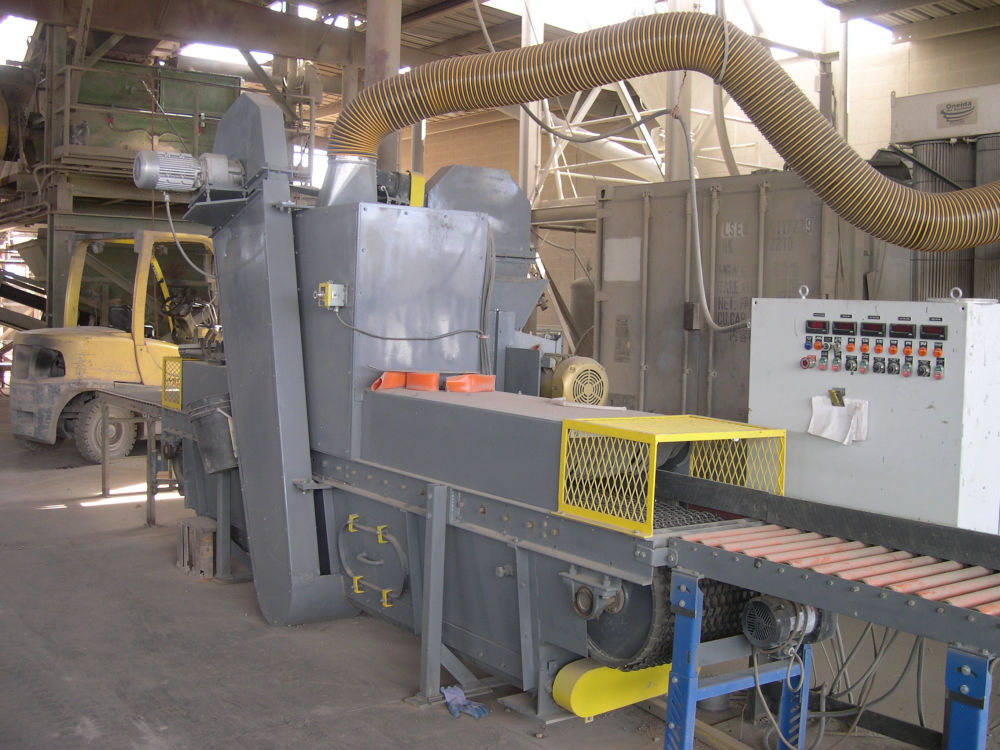

The unit is comprised of a single blast head delivering shot medium to the side of the masonry products. The shot from the blast head is vectored to a concentrated impact zone, which increases the shot impact effectiveness. The side delivery concept allows the masonry units to be processed cores vertical, so less shot is deposited on the top flat surfaces. Other innovative features incorporated in the Model 380 is an extra heavy duty auger with opposing flights, that collect and coveys the shot to a single transfer point where the unique v-belt driven bucket elevators lift the shot to a two-stage trammel.

The trammel with the two screen sizes separates the shot from fine or dust, and then segregates the shot from any large debris. The system, in tandem with a high volume dust collect / filtration system, maintains the steel shot with the cleanest possible consistency. With clean constant shot, a more reliable continuous delivery of shot is maintained.

Product is maintained by VFD mesh belt, that is auto-adjusted in combination to the shot head amperage being used.